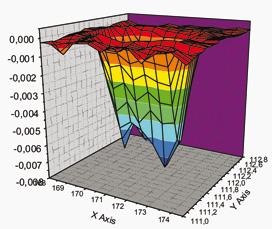

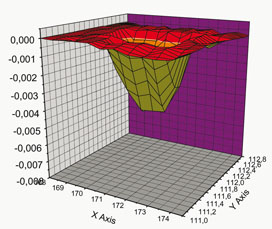

Fig. Wear scratch profile of standard silver (left) and of DiamoSilb-Silver (right)

Silver coatings are often used to increase the conductivity and corrosion stability of copper in electrical connectors, switches, circuit boards etc. In electroplating, silver is primarily used in industrial applications, especially for the power generation and distribution equipment. Even in telecom, automotive, jewelry and cutlery silver is widely used as a finishing material.

The main drawback of silver is its poor mechanical stability and high friction coefficient. Finding a solution to reduce wear and friction is therefore of exceptional interest.

In the 1970s industry began to use graphite microparticles as an additive in silver electroplating processes. Graphite leaded to a remarkable reduction of friction, though no increase of mechanical stability could be registered.

Few years ago PlasmaChem GmbH developed a new method of increasing mechanical stability of electroplated silver by using nanoparticles as an additive to plating electrolytes. The best results were achieved when specially pretreated detonation nanodiamonds were employed.

PlasmaChem’s nano-additives (DiamoSilb® and AlumoSilb®) lead to the formation of smaller metal crystallites (and a smaller distance between crystallites) during the electroplating process. As a consequence, the elasticity, abrasion resistance and hardness of the metal increase and friction coefficient decreases. The amount of nanoparticles getting co-deposited with the metal is tiny (below 0.1%), nevertheless, their presence decreases both wear and friction coefficient by 60%. Simultaneously, the electrical conductivity of silver remains unaltered.

By using these novel additives, one can either increase the life-time of the final device, or reduce the thickness of the plating, and therefore the consumption of silver by 2-3 times.

The improvement of product quality is usually closely connected with additional investments for the development of new production lines, purchase of equipment and changes of manufacturing logistics. In the case of the nano-additives, no major investments are needed. The nanoparticles suspension should be added directly to the existing electroplating bath. This allows also small and medium companies to benefit from this new technology without substantial investments.

Electroplating additives can be used not only for silver plating. Successful results were achieved also for gold, chromium, nickel, copper, zinc and many other metals. PlasmaChem has launched production of DiamoGold™, DiamoChrom™ and DiamoHard™-N for gold, chromium and nickel electrolytes respectively.

Standard Silver |

DiamoSilb®-Silver |

|

Friction coefficient |

100 % |

40 - 60 % |

Wear |

100 % |

40 - 60 % |

| Hardness | 100 % | 115-130 % |